For the preparation of water in public pools traditionally sand filtration is used in combination with additional process steps. This well and long-established technology is outstanding due to small water consumption but exhibits some impairment in terms of filtration efficiency regarding micro-organisms.

Therefore, ultrafiltration with polymer membranes has been increasingly used for a couple of years for pool water preparation purposes. The ultrafiltration membranes provide a physical barrier for bacteria and viruses in the nanometer-scale, thus resulting in a very good water quality. Unfortunately, the use of ultrafiltration systems leads to higher water consumption in many cases, which leads to an undesired increase of the operating costs for the pool operator

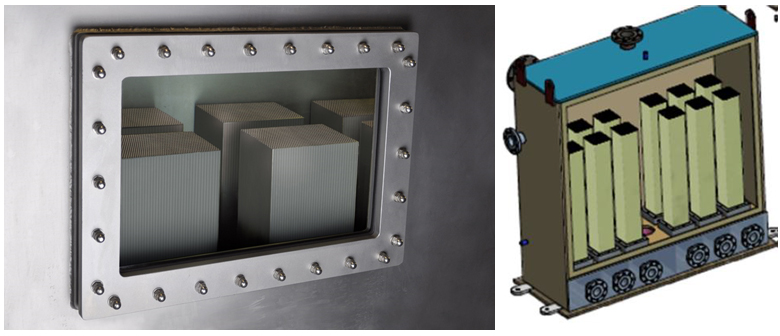

CRYSTAR® FT ceramic Membrane Filters for the preparation of pool water in public pools, together with additional process steps, uniquely combine the advantages of small water consumption and high-water quality and represent real and new alternative to the known filtration techniques CRYSTAR® FT Ceramic Membrane Filters for the preparation of pool water in public pools are a further development of Saint-Gobain’s diesel particulate filters, which are used in the automotive business. CRYSTAR® FT Ceramic Membrane Filters for the preparation of pool water in public pools are operated in dead-end mode, which means, the complete pool water has to pass the porous, filtration-active membrane, ensuring that all particles are held back by the membrane.

ADVANTAGES OF CRYSTAR® FT CERAMIC MEMBRANE FILTERS

The use of CRYSTAR® FT Filters ensures the following advantages:

- physical barrier for bacteria and micro-organisms

- high efficiency

- excellent chemical robustness

- long service time

- high flux

- effective disinfection

- simple cleaning

- reduced chlorine consumption

- without pH-restrictions

- small operating costs

- compact design

An important advantage of CRYSTAR® FT ceramic Membrane Filters for the preparation of pool water in public pools is their ability to be cleaned even under extreme chemical conditions (e.g. at pH 0.5 and pH 13.5). After such cleaning, the filters are practically in “as delivered”-state, system design supports this, the filters can remain mounted in the system for the chemical cleaning and are ready for filtration immediately afterwards (ClP “Clean in Place”). Due to the outstanding material properties of silicon carbide, the chemical cleaning can be repeated as often as required to ensure a long service time.

CRYSTAR® FT HiFlo

| Cross section dimension | mm – in | 149 x 149 – 5 7/8 x 5 7/8 |

| Cross section dimension | mm – in | 149 x 149 – 5 7/8 x 5 7/8 |

| Standard lengths * | mm – in | 1000 – 39 3/8 |

| Channel hydraulic diameter | mm – in | 1,9 mm – 0,0748 in |

| Filtration area | m² – ft² | 11.0 – 118.5 |

| Weight (without flange) | kg – lbs | 19 – 42 |

| Chemical composition | SiC >99% | |

| Membrane pore size ** | μm | 4.0 |

| Flux with clean water, 20°C / 68°F at 1 bar / 14.5 psi |

LMH – GFD | 25000 – 14700 |

| Recommended flow rate for pool water | m3/h | 14 – 20 |

| Recommended flow rate for pool water | gpm | 61 – 88 |

| TMP recommended | bar – psi | up to 0.6 – 8.7 in vacuum mode up to 1.0 – 14.5 in pressure mode |

| Backwash recommended | bar – psi | up to 2.0 – 29.0 |

| pH range | pH | 0 – 14 |

| Temperature range | °C – °F | Up to 65°C – 150°F with flange |

| Up to 500°C – 930°F without flange | ||

| Standard lengths * | mm – in | 1000 – 39 3/8 |

| Channel hydraulic diameter | mm – in | 1,9 mm – 0,0748 in |

| Filtration area | m² – ft² | 11.0 – 118.5 |

| Weight (without flange) | kg – lbs | 19 – 42 |

| Chemical composition | SiC >99% | |

| Membrane pore size ** | μm | 4.0 |

| Flux with clean water, 20°C / 68°F at 1 bar / 14.5 psi |

LMH – GFD | 25000 – 14700 |

| Recommended flow rate for pool water | m3/h | 14 – 20 |

| Recommended flow rate for pool water | gpm | 61 – 88 |

| TMP recommended | bar – psi | up to 0.6 – 8.7 in vacuum mode |

| up to 1.0 – 14.5 in pressure mode | ||

| Backwash recommended | bar – psi | up to 2.0 – 29.0 |

| pH range | pH | 0 – 14 |

| Temperature range | °C – °F | Up to 65°C – 150°F with flange Up to 500°C – 930°F without flange |

CRYSTAR® FT HiPur

| Cross section dimension | mm – in | 149 x 149 – 5 7/8 x 5 7/8 |

| Cross section dimension | mm – in | 1000 – 39 3/8 |

| Standard lengths * | mm – in | 1,9 mm – 0,0748 in |

| Channel hydraulic diameter | mm – in | 11.0 – 118.5 |

| Filtration area | m² – ft² | 19 – 42 |

| Weight (without flange) | kg – lbs | SiC >99% |

| Chemical composition | 0.25 | |

| Membrane pore size ** | μm | 4000 – 2352 |

| Flux with clean water, 20°C / 68°F at 1 bar / 14.5 psi |

LMH – GFD | 5 – 10 |

| Recommended flow rate for pool water | m3/h gpm |

22 – 44 up to 0.6 – 8.7 in vacuum mode |

| TMP recommended | bar – psi | up to 1.0 – 14.5 in pressure mode up to 2.0 – 29.0 |

| Backwash recommended | bar – psi | 0 – 14 |

| pH range | pH | Up to 65°C – 150°F with flange |

| Temperature range | °C – °F | Up to 500°C – 930°F without flange 149 x 149 – 5 7/8 x 5 7/8 |

| Standard lengths * | mm – in | 1000 – 39 3/8 |

| Channel hydraulic diameter | mm – in | 1,9 mm – 0,0748 in |

| Filtration area | m² – ft² | 11.0 – 118.5 |

| Weight (without flange) | kg – lbs | 19 – 42 |

| Chemical composition | SiC >99% | |

| Membrane pore size ** | μm | 0.25 |

| Flux with clean water, 20°C / 68°F at 1 bar / 14.5 psi |

LMH – GFD | 4000 – 2352 |

| Recommended flow rate for pool water | m3/h gpm |

5 – 10 22 – 44 |

| TMP recommended | bar – psi | up to 0.6 – 8.7 in vacuum mode up to 1.0 – 14.5 in pressure mode |

| Backwash recommended | bar – psi | up to 2.0 – 29.0 |

| pH range | pH | 0 – 14 |

| Temperature range | °C – °F | Up to 65°C – 150°F with flange Up to 500°C – 930°F without flange |